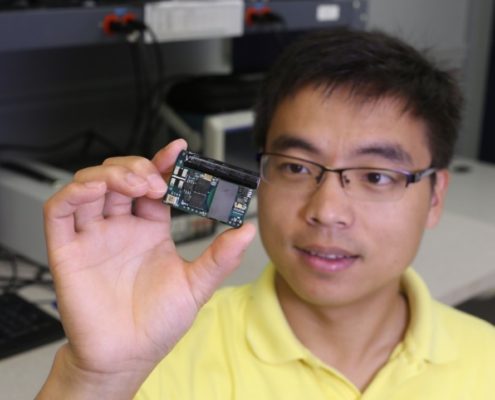

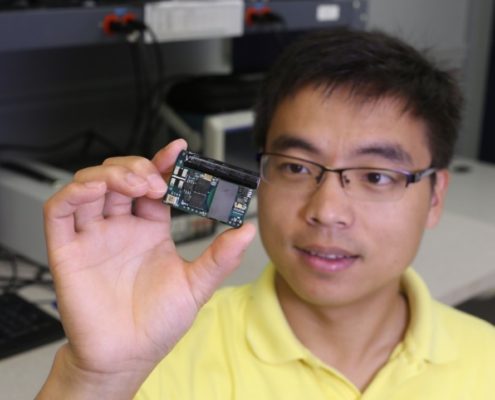

A Virginia Tech researcher displays the high-density wall adapter for laptop computers.

A feature story released by the White House on its blog June 28 details how PowerAmerica and other members of the National Network of Manufacturing Institutes are sharpening the nation’s competitive edge through their work.

The blog post is a “snapshot of the revolutionary technologies showing why America continues to be the most innovative, entrepreneurial country in the world.”

PowerAmerica is featured as the 8th example for its work in miniaturizing electronics.

“PowerAmerica in Raleigh, NC is testing the limits of portable electronics. With their new semiconductor technology, they envision shrinking your laptop charger to the size of a keyring and your power station down to the size of a refrigerator using power electronics,” the article states.

The photo accompanying the article features a researcher from PowerAmerica member Virginia Tech. Led by Dr. Fred Lee and Dr. Qiang Li, the team is working on a high density adapter for laptop computers that will reduce the size of the wall adapter by more than 50 percent, increasing transportability and energy efficiency.

Virginia Tech’s Partnership with PowerAmerica

The Virginia Tech team, like other academic partners of PowerAmerica, has greatly benefitted from the unique connections offered through the Institute. The university researchers are in talks with Navitas, another PowerAmerica member, to gain advice on how to best commercialize the technology for the marketplace. Another member, Transphorm, has loaned the team devices that have proven critical to their research.

Because of the partnership with PowerAmerica, the team has been able to focus their efforts very specifically on wide bandgap technology in a way that would not be possible otherwise. This has led to widespread interest from outside companies across the United States, including Texas Instruments and ON Semiconductor, both of which have approached the Virginia Tech team to learn more about their work.

With the support of PowerAmerica, “we’re not just writing whitepapers,” Dr. Qiang Li from Virginia Tech said, “we’re connecting with industry and addressing real problems.”

The group participated in a variety of hands-on activities designed to increase their understanding of the role of power, and specifically wide bandgap semiconductors. In addition to constructing their own robots and devices powered by wide bandgap technology, they visited the various lab projects in the FREEDM Engineering Systems Center at N.C. State, toured the nearby facilities of global power technology company ABB, and took a trip to the N.C. State solar farm.

The group participated in a variety of hands-on activities designed to increase their understanding of the role of power, and specifically wide bandgap semiconductors. In addition to constructing their own robots and devices powered by wide bandgap technology, they visited the various lab projects in the FREEDM Engineering Systems Center at N.C. State, toured the nearby facilities of global power technology company ABB, and took a trip to the N.C. State solar farm.

PowerAmerica will be represented at the SEMICON West conference

PowerAmerica will be represented at the SEMICON West conference