PowerAmerica Offers Short Course on SiC and GaN Power Electronics Technology

As part of its ongoing efforts to accelerate the development of a highly educated wide bandgap power electronics manufacturing workforce, PowerAmerica will offer a Wide Bandgap Devices and Applications short course Nov. 7-9 at its offices in Raleigh.

“This course was tailored very specifically to meet the current needs of the power electronics industry. We sought input from more than 20 industry leaders to determine existing workforce knowledge gaps, then analyzed this information in detail to create a course that will equip attendees with the tools needed to succeed in this quickly accelerating technological field,” said PowerAmerica Deputy Executive Director and CTO Victor Veliadis.

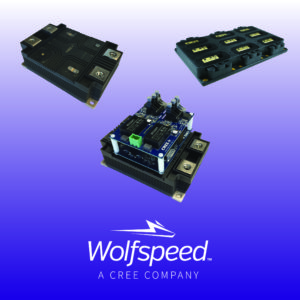

The goal is to introduce power electronics professionals to the basics and benefits of silicon carbide and gallium nitride technology, so they can effectively incorporate it into their products and systems. Power electronics applications engineers, power device engineers, SiC and GaN technical marketing professionals, and power electronics business and product line managers are all encouraged to attend.

Led by a team of wide bandgap technology experts from industry and academia, the course will provide participants with experience through applications-specific examples in areas such as power converters, electric vehicles and motor drives, as well as a hands-on laboratory demos.

The course is available for $1,200 for PowerAmerica members and $1,800 for non-members. View the full schedule and register here.

Dr. Ayayi Ahyi of Auburn University will speak about his work to develop a gate dielectric process that will be an improvement on the current nitridation process and made freely available to PowerAmerica members during PowerAmerica’s monthly technical webinar series from

Dr. Ayayi Ahyi of Auburn University will speak about his work to develop a gate dielectric process that will be an improvement on the current nitridation process and made freely available to PowerAmerica members during PowerAmerica’s monthly technical webinar series from  Through PowerAmerica, John Deere has formed a collaboration with researchers from the Department of Energy National Renewable Energy Laboratory to develop a 200 kW 1050 VDC silicon carbide-based inverter. The inverter will convert vehicle engine power into electrical power needed for hybrid motors in heavy duty construction vehicles.

Through PowerAmerica, John Deere has formed a collaboration with researchers from the Department of Energy National Renewable Energy Laboratory to develop a 200 kW 1050 VDC silicon carbide-based inverter. The inverter will convert vehicle engine power into electrical power needed for hybrid motors in heavy duty construction vehicles. PowerAmerica is proud to welcome the Research Triangle Cleantech Cluster (RTCC) as an Associate Member.

PowerAmerica is proud to welcome the Research Triangle Cleantech Cluster (RTCC) as an Associate Member.