Celebrating 10 Years of Energizing the WBG Semiconductor Industry

Over the last decade, we've supported hundreds of research, education and outreach projects to bolster the domestic manufacturing — from fab to foundry — of wide bandgap (WBG) semiconductor chips and electronics, which are crucial to powering countless products of both today and tomorrow.

By the Numbers

216

Research projects funded by PowerAmerica and completed by members

400+

Former undergraduate and graduate student researchers now working in industry and academia

7,000+

Attendees at PowerAmerica tutorials, short courses and webinars

20+

Patents generated by PowerAmerica and its members

80+

Publications in peer-reviewed journals on PowerAmerica-funded projects

18,000+

Total learners taught, from K-12 students to Ph.D.’s

Our History

-

December 2014

U.S. Dept. of Energy establishes the Next Generation Power Electronics National Manufacturing Innovation Institute, now known as PowerAmerica.

-

January 2015

PowerAmerica Institute officially begins operations on NC State University’s Centennial Campus.

-

Jan. 21, 2015

U.S. Army Maj. Gen. (Ret.) Nick Justice named executive director of PowerAmerica.

-

July 2, 2019

Victor Veliadis, Ph.D., CTO of PowerAmerica since 2016, takes over as executive director.

-

April 2020

PowerAmerica publishes the final version (4.2) of Technology Roadmap.

-

April 2021

PowerAmerica proudly becomes self-sustaining — supported solely by members, user fees and other revenues.

-

October 2022

Executive Director and CTO Victor Veliadis speaks at White House panel, for the first leadership summit convening all 16 Manufacturing USA Institutes’ directors.

-

November 3, 2022

Undersecretary of Commerce Don Graves visits PowerAmerica at NC State to discuss its win of the NIST $5M program on “Building Pandemic Resilience.”

-

September 2024

PowerAmerica 2.0 – $64M award from the Department of Energy.

The First DOE-Funded M-USA Institute

PowerAmerica is proud to be the first Manufacturing USA Institute founded thanks to funding from the U.S. Department of Energy (DOE). We’re sincerely grateful for its generous support.

DOE’s strategic investment in PowerAmerica has returned significant energy resilience, economic, high-tech job creation and national security benefits.

A Decade of Partnership

From startups to large companies, Manufacturing USA helps members grow, thrive and shape the future of U.S. manufacturing. A decade of partnership and progress shows one thing clearly — collaboration powers innovation. Watch the video above to see how (catch PowerAmerica Executive Director and CTO Victor Veliadis around the 2:30 mark).

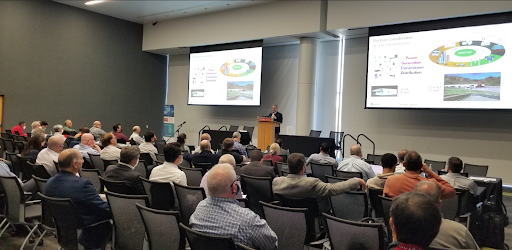

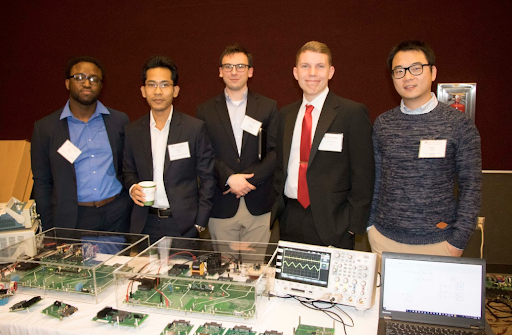

PowerAmerica Events Throughout the Years

Look back on some highlights from our Short Courses, Summer Workshops and Annual Meetings

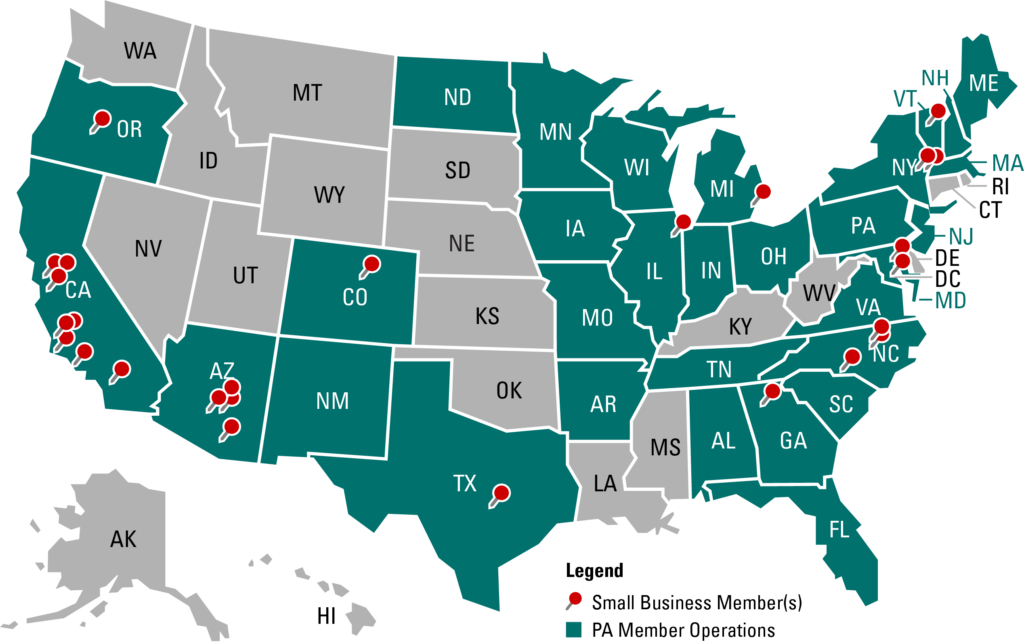

Driving Innovation in Semiconductor Manufacturing from Coast to Coast

Our Current Members

Member Spotlight: Commercialization Success Stories

The following stories are just a few examples of the many successes we’ve shared with our members over the past decade.

X-FAB

With support from us and other stakeholders, longtime PowerAmerica member X-FAB built the first open silicon carbide (SiC) foundry in the U.S. — increasing the domestic production of SiC chips.

Establishing America’s First SiC Foundry

We worked with X-FAB and other stakeholders to build the first open SiC chip factory in the U.S. Located in Lubbock, Texas, the X-FAB foundry operates under a collaborative model, providing fabrication capabilities to SiC semiconductor companies that don’t have in-house fabrication facilities. As the only high-volume SiC foundry in the U.S., X-FAB has become a vital resource for domestic SiC production — helping curb the migration of critical SiC semiconductor manufacturing overseas.

To learn more, check out some of the media attention X-FAB and PowerAmerica received about this significant accomplishment:

- PowerAmerica: Investing in Industry to Advance the Next Generation of Power Electronics (Source: U.S. Dept. of Energy)

- Onshoring Semiconductors In Lubbock (Source: ChiefExecutiveGroup magazine)

- X-Fab announces $200 million expansion, creates 250 new jobs (Source: KCDB 11 News)

GeneSiC, Monolith and United Silicon Carbide

GeneSiC (acquired by Navitas), Monolith (acquired by Littelfuse) and United Silicon Carbide (acquired by onsemi) are three companies that all leveraged fellow PowerAmerica member X-FAB’s U.S. foundry to fabricate devices.

Supporting Startups and Making U.S. SiC Chip Manufacturing Flourish

GeneSiC, Monolith and United Silicon Carbide — which all joined PowerAmerica as small-business members — were among many U.S. companies that leveraged fellow PowerAmerica member X-FAB’s foundry in Lubbock, Texas.

GeneSiC would eventually go on to become acquired by another PowerAmerica member, Navitas Semiconductor, which was expanding its GaN portfolio to include SiC chips. Monolith was later acquired by Littelfuse, and USiC was recently acquired by onsemi — one of the world’s largest SiC manufacturers.

John Deere

John Deere and the National Renewable Energy Laboratory (NREL) partnered through PowerAmerica to develop a 200 kW 1050 V SiC Traction Inverter — significantly accelerating the company’s electrification efforts for off-road equipment.

Juicing Up John Deere’s Electric Equipment

In collaboration with John Deere, one of the largest global agriculture equipment manufacturers in the world, and under the umbrella of the U.S. Department of Energy’s PowerAmerica program, NREL researchers helped craft a 200-kilowatt, 1,050-volt SiC traction inverter with never-before-seen performance, capable of roughly 400% greater power density than previous silicon-only designs.

Heavy-duty vehicles from John Deere Electronic Solutions (JDES) could benefit from these types of inverter technologies as some of their heavy-duty vehicle engine coolant system temperatures can reach up to 115°C.

To learn more, read this news release: NREL-Developed Silicon Carbide Inverter Part of Production-Intent Program at John Deere (Source: National Renewable Energy Laboratory).

Member Testimonials

“PowerAmerica does a fantastic job engaging some of the greatest minds in the wide bandgap semiconductor industries, both from the producers and users of the technologies,”

“It was an incredible experience presenting our research and receiving valuable feedback from professionals,”

“Membership in PowerAmerica provides Texas Instruments the opportunity to influence the important research being done in wide bandgap technology,”

“PowerAmerica opened the door for me to work directly with GaN transistors as an undergraduate, and the Summer Workshop was a fantastic way to learn more about the field … from a range of industry experts,”

“PowerAmerica advanced John Deere’s wide bandgap power electronics R&D work by more than five years,”

Our Founding Members

PowerAmerica’s membership has grown steadily throughout the years. Today, our consortium includes nearly 100 members in total — spanning industry, academia, and national labs — and we’re thankful for each and every one of them.

However, as we look back on our last 10 years, we’d be remiss not to highlight the 20 members who were among the first to join.

What We Do and Why It Matters

Listen to our executive director and chief technical officer, Victor Veliadis, explain in less than 60 seconds how the work we do in partnership with our member organizations to revitalize the U.S. manufacturing industry, strengthen national security and modernize electrical infrastructure.