Report Says Manufacturing USA ‘Is a Valid Approach’

A recent report by a consulting company commissioned by the Manufacturing USA network of Institutes found the institutes to be a “valid approach,” that “attracts significant and meaningful participation from industry, academia, and local, state and federal government.” Read the full manufacturingusa.com article on the report here, and find a full link to the report here.

Examples of PowerAmerica’s work appears several times throughout the report, which was prepared by Deloitte Consulting LLP. PowerAmerica was specifically recognized for asset pooling that enables small-scale production (pg. 17):

Silicon carbide and gallium nitride are critical materials for the emerging field of power electronics. The silicon carbide and gallium nitride markets are dominated by relatively few players. There is a need for innovation from start-up entrepreneurs advancing disruptive technologies. However, dozens of smaller fabrication plants have closed their doors since 2001 because of competition. X-FAB, with funding from PowerAmerica, pools the production of semiconductors from small companies

to achieve economies of scale. IP from each company is protected, but innovation is fostered because of X-FAB’s ability to aggregate demand across customers.

Dr. Jay Baliga of N.C. State University will speak about the ongoing effort at N.C. State to create an open foundry process at X-Fab in support of PowerAmerica’s mission to encourage more participation in manufacturing SiC power MOSFETs during the monthly technical webinar series from 12:30 p.m.

Dr. Jay Baliga of N.C. State University will speak about the ongoing effort at N.C. State to create an open foundry process at X-Fab in support of PowerAmerica’s mission to encourage more participation in manufacturing SiC power MOSFETs during the monthly technical webinar series from 12:30 p.m. Dr. Subhashish Battacharya of N.C. State University will speak about his work to develop and demonstrate the commercial grade intelligent gate driver and interface system for SiC devices during PowerAmerica’s monthly technical webinar series from

Dr. Subhashish Battacharya of N.C. State University will speak about his work to develop and demonstrate the commercial grade intelligent gate driver and interface system for SiC devices during PowerAmerica’s monthly technical webinar series from

PowerAmerica has developed baseline 1200-V MOSFET and 1200-V Integrated MOSFET/JBS SiC fabrication processes at XFAB’s 150mm SiC foundry in Lubbock, Texas that can significantly accelerate development of a company’s wide bandgap technology offerings.

PowerAmerica has developed baseline 1200-V MOSFET and 1200-V Integrated MOSFET/JBS SiC fabrication processes at XFAB’s 150mm SiC foundry in Lubbock, Texas that can significantly accelerate development of a company’s wide bandgap technology offerings.

With support from PowerAmerica, member AgileSwitch has applied a new patented switching technique to provide enhanced control in high-power SiC applications.

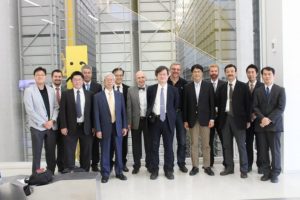

With support from PowerAmerica, member AgileSwitch has applied a new patented switching technique to provide enhanced control in high-power SiC applications. PowerAmerica recently had the honor of hosting a delegation of professors and administrators from Nagoya University in Japan, including Dr. Hiroshi Amano, who received the Nobel Prize in Physics in 2014 for “the invention of efficient blue light-emitting diodes which has enabled bright and energy-saving white light sources.” The purpose of the visit was to explore future opportunities in the fields of power electronics and wide bandgap semiconductors.

PowerAmerica recently had the honor of hosting a delegation of professors and administrators from Nagoya University in Japan, including Dr. Hiroshi Amano, who received the Nobel Prize in Physics in 2014 for “the invention of efficient blue light-emitting diodes which has enabled bright and energy-saving white light sources.” The purpose of the visit was to explore future opportunities in the fields of power electronics and wide bandgap semiconductors.